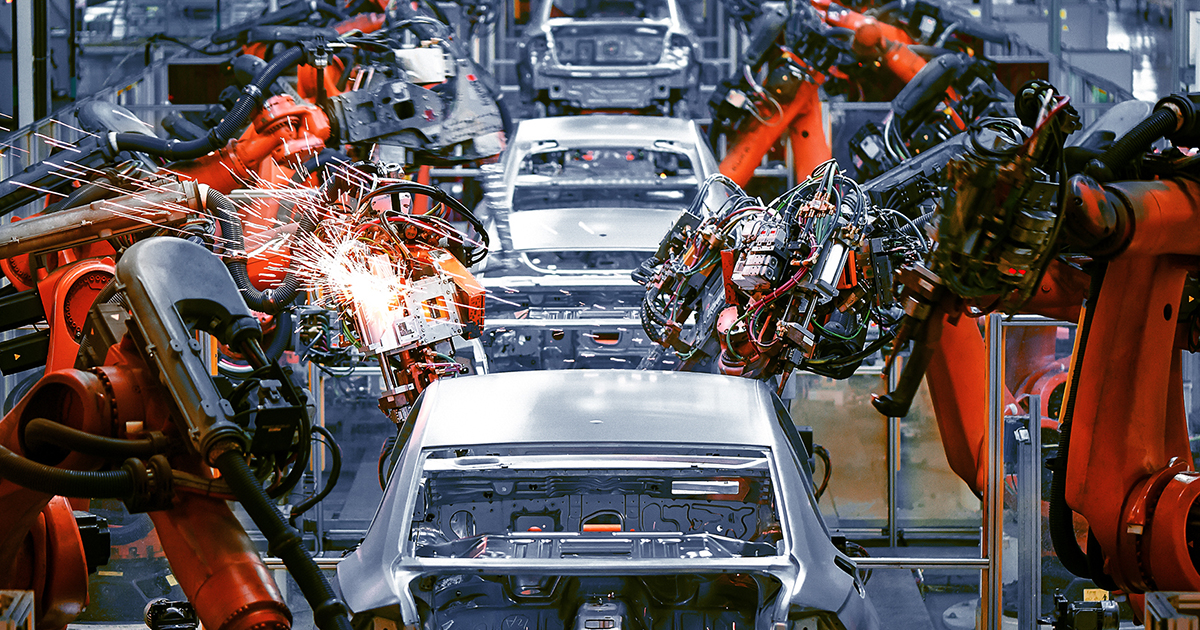

The welding arm on the automobile production line is being welded; Shutterstock ID 732811756; Purchase Order: 200438; Job: 200438; Client/Licensee: Siemens AG; Other: Antonia Hoepffner

In the intricate realm of manufacturing, distinct methodologies cater to the diverse needs of industries. One such paradigm is discrete manufacturing. This article delves into the definition and intricacies of discrete manufacturing, shedding light on the distinctive characteristics that set it apart in the world of precision production.

**1. **Defining Discrete Manufacturing:**

*Overview:* Discrete manufacturing refers to the production of distinct items—products that are individually identifiable and separate. Unlike its counterpart, process manufacturing, which deals with continuous production of goods such as chemicals or beverages, discrete manufacturing focuses on creating unique, countable units. This methodology is prevalent across industries producing items like automobiles, electronics, machinery, and consumer goods.

**2. **Characteristics of Discrete Manufacturing:**

*Overview:* The hallmark of discrete manufacturing lies in the individuality of its products. Each unit is identifiable, often with a unique serial number or identifier. This approach contrasts with process manufacturing, where products are indistinguishable from one another. Discrete manufacturing is characterized by distinct, often complex, assembly processes involving various components.

**3. **Product Variability and Customization:**

*Overview:* Discrete manufacturing thrives in environments where product variability and customization are paramount. Industries producing items with unique specifications or configurations leverage discrete manufacturing to accommodate diverse customer requirements. This adaptability allows for the creation of tailored solutions, from intricate machinery to personalized electronics.

**4. **Assembly Line Precision:**

*Overview:* Precision in assembly is a cornerstone of discrete manufacturing. The production process is often organized into assembly lines, where components come together with meticulous accuracy to create the final product. This precision ensures the consistency and quality of each unit, aligning with the industry’s focus on reliability and performance.

**5. **Batch Production and Job Shops:**

*Overview:* Discrete manufacturing accommodates both batch production and job shop environments. Batch production involves creating a specific quantity of identical products, while job shops cater to unique, one-off items. This versatility allows manufacturers to adapt to varying production needs, balancing efficiency with customization.

**6. **Technological Integration:**

*Overview:* Technology plays a pivotal role in the realm of discrete manufacturing. Advanced manufacturing technologies, such as Computer Numerical Control (CNC) machining, robotics, and digitalization, enhance precision and efficiency. These technologies streamline production processes, reduce lead times, and contribute to the overall agility of discrete manufacturing operations.

**7. **Supply Chain Dynamics:**

*Overview:* The dynamics of the supply chain in discrete manufacturing are intricate. Unlike process manufacturing, which often deals with bulk materials, discrete manufacturing involves managing a diverse array of components and materials. Effective supply chain management is essential to ensure the timely availability of parts for assembly, minimizing downtime and optimizing production schedules.

**8. **Quality Control and Traceability:**

*Overview:* Quality control is paramount in discrete manufacturing. Each unit undergoes rigorous inspection to meet defined standards. Additionally, traceability is a key consideration, with the ability to track and trace individual units throughout the production process. This ensures accountability, facilitates recalls if necessary, and upholds the integrity of the manufacturing process.

**Conclusion:**

Discrete manufacturing stands as a pillar of precision production, where individuality, customization, and assembly line efficiency converge. From intricate electronics to sophisticated machinery, industries embracing discrete manufacturing find a balance between standardized processes and the flexibility to meet diverse customer needs. As technology continues to evolve, the landscape of discrete manufacturing will undoubtedly witness further advancements, shaping the future of precision production across a multitude of sectors.